What's is the Difference Between a Wet and Dry Sprinkler Riser

Sprinkler systems are the most effective manner to suppress a fire. A simple sprinkler system has a pipe full of water and sprinkler heads. When heat triggers a sprinkler head, water is immediately discharged. This is called a WET SPRINKLER SYSTEM because the pipes are always full of water.

A wet sprinkler system has a water flow sensor. The most common sensors have an impeller that spins with water flow, however, there are many methods that can be used to determine water flow.

In locations where the pipes are located in unheated spaces and may potentially freeze, the pipes are not full of water. They are full of pressurized air, or sometimes nitrogen which reduces corrosion in the pipe. In our example, we will use air since it is far more common. This is called a DRY SPRINKLER SYSTEM.

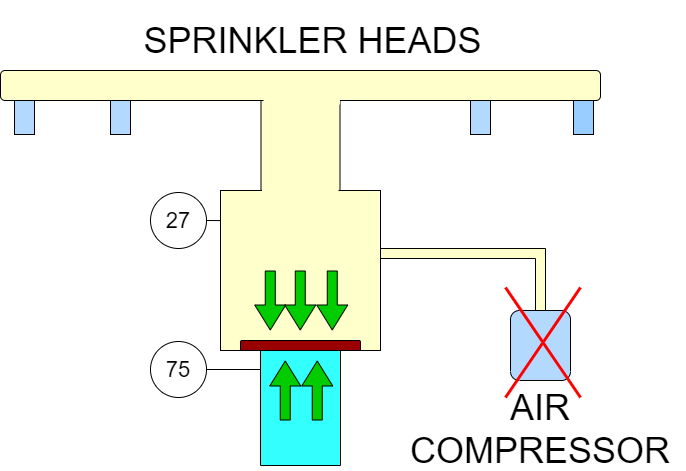

An air compressor maintains sufficient pressure to keep a valve closed. Because the surface area is larger on the air side, it takes less air pressure to hold back water pressure even twice as high. Each system is different and the values illustrated are only for this example. All values are in PSI.

In the illustration above you can see the air pressure has dropped. At a specific set point, the air compressor turns on. The air pressure is restored, and all is good.

When a sprinkler head opens, from fire or damage, the air rushes out lowering the pressure needed to keep the valve closed.

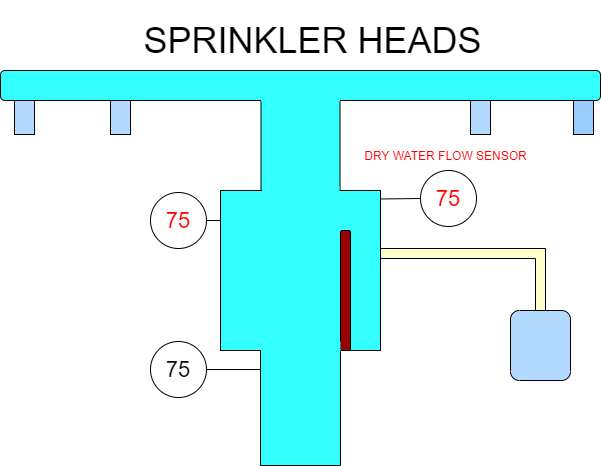

The air compressor can no longer maintain the air pressure required to hold back the water. When the valve opens letting the water flow into the pipe, the air pressure gauge will match the water pressure reading as seen below.

Unlike the wet system with a mechanical device that moves with water flow, the dry system counts on the fact that if you have the water pressure inside the dry pipe, which is higher than the air pressure usually present, then you must have a fire. A separate Dry Flow sensor monitors for the higher pressure of water present in the system. When the DRY WATER FLOW SENSOR (just a pressure gauge) reaches a value that under normal conditions should not exist, A DRY WATER FLOW Fire Alarm is triggered

However, there is a flaw in that logic.

In cases of air compressor failure, or an air leak too large for the compressor to maintain the system pressure, the air pressure drops in the same manner as an open sprinkler head, albeit at a slower rate.

If the air pressure drops too low, the fire alarm panel will signal a Supervisory Condition of "LOW AIR". The fire panel will start beeping and the monitoring station will call to notify the user of the LOW AIR alert.

If the user fails to respond to a LOW AIR warning, the valve will eventually open.

Just like in a real fire event, water pressure on the dry side of the valve will trigger a DRY WATER FLOW event. Fire Trucks will roll. There is no fire, but there is water inside a system not intended to hold water, especially if it's cold outside. Frozen sprinkler pipes cause untold millions in water damage each year.

LOW AIR Alerts should never be ignored or pushed back even a few hours. LOW AIR alerts should be addressed with the sprinkler contractor or maintenance company immediately.