The Do's, Don'ts and Never's of Drilling Beams.

Incorrect drilling of beams is a significant issue on any job site. Modern building methods use increasingly complex engineered materials and designs. Drilling ANY hole in an engineered beam can lead to a considerable cost to replace or repair which may all be billed back to your company.

If you see that no other trade drilled through a beam, don't be the first!!

When entering a new job site, you should verify with your supervisor what structural members can and cannot be drilled and if so, what methods can be used. This also includes steel framing. If you are alone, seek out the general contractor and ask them if they can perform a job walk to discuss your intentions.

There are several types of beams and each one has its own set of rules. What you may have been allowed to do on one job may not be allowed on another.

In situations where you know you can drill, there are standard rules and methods you should observe.

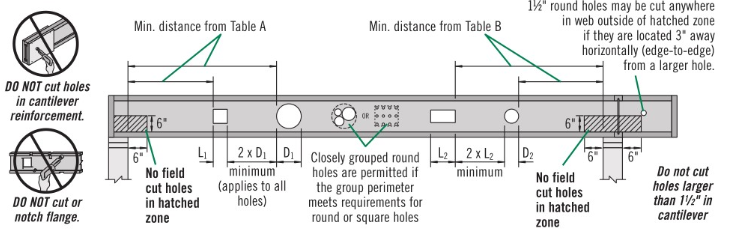

1. NEVER drill a hole within 1' of the end of any beam or a floor joist. You should also avoid drilling within 1' of where a beam sits on top of a support column or post.

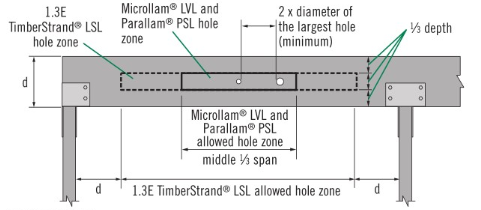

2. On overhead spans, the 1/3 1/3 rule generally applies. Only drill within the 1/3 middle of the span horizontally and the 1/3 middle vertically.

3. Never drill holes of the same size next to each other. Vary the vertical location of holes. This includes existing holes.

4. Drilling several smaller holes at varying elevations on the beam is better than 1 large hole.

Every manufacturer provides installation manuals that detail allowed holes.

Below is an example of the 1/3 - 1/3 rule. In some cases, the architect and(or) structural engineer may forbid drilling using the 1/3-1/3 rule. As an installer, it is your responsibility to fully understand the rules that apply to a specific job site.

Typical engineered wood beam

The file below is a Product Installation Guide which every manufacturer will usually have available on their website. Being familiar with these guides is a good idea. Take a look.